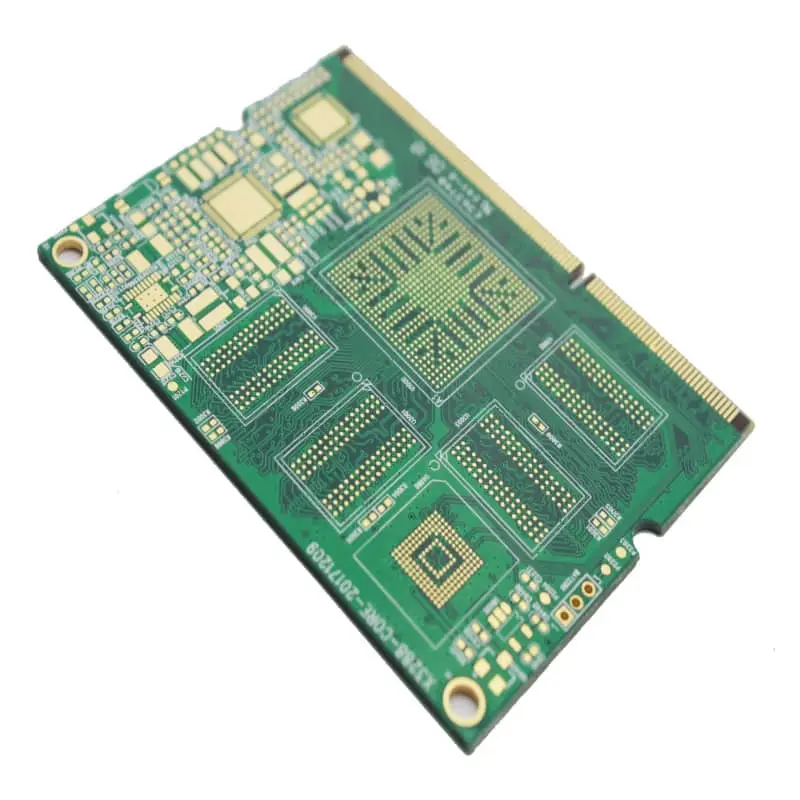

Quick Turn PCB Assembly is a specialized manufacturing service that prioritizes rapid turnaround of printed circuit board (PCB) assembly without compromising quality, designed to meet the urgent needs of industries ranging from electronics startups to medical device manufacturers. In today’s fast-paced manufacturing landscape, where time-to-market can make or break a product’s success, quick turn PCB assembly has become an indispensable solution for businesses seeking to accelerate prototyping, address emergency production gaps, or fulfill low-volume, time-sensitive orders.

1、Understanding Quick Turn PCB Assembly: Basics and Core Value

1.1 Definition of Quick Turn PCB Assembly

At its core, quick turn PCB assembly refers to the process of fabricating and assembling PCBs in a significantly shortened timeframe compared to traditional PCB assembly—typically between 24 hours to 7 days, depending on the complexity of the board and order volume. Unlike standard assembly services that may take 2–6 weeks to complete, quick turn services streamline every stage of production, from design review to final testing, to deliver functional, high-quality boards faster. This speed does not come at the cost of precision; reputable providers maintain compliance with industry standards like IPC-A-610 to ensure reliability.

1.2 Key Benefits of Quick Turn PCB Assembly

Businesses choose quick turn PCB assembly for its ability to solve time-critical challenges, but its value extends beyond speed. Below are the most impactful benefits, tailored to address mid-to-late stage (MOFU/BOFU) buying needs:

- Accelerated Time-to-Market: Reduces product development cycles by up to 70%, allowing companies to launch new products weeks earlier than competitors using traditional assembly methods. For startups and tech firms, this can be the difference between leading the market and falling behind.

- Cost Savings on Rework and Delays: Early prototyping with quick turn assembly identifies design flaws in days rather than weeks, preventing costly rework later in production. A 2025 industry study found that DFM (Design for Manufacturability) checks in quick turn processes prevent 65% of potential delays, saving businesses an average of 20–30% on production costs.

- Flexibility for Low-Volume Orders: Ideal for low-volume production (1–1,000 units), which is critical for pre-market testing, emergency replacements, or niche market products. This flexibility eliminates the need to commit to large, costly batches when demand is uncertain.

- Reliable Emergency Support: Addresses unexpected production gaps or equipment failures, minimizing downtime. For industrial and medical device manufacturers, this ensures continuity in operations where even a single day of downtime can cost tens of thousands of dollars.

1.3 Common FAQs About Quick Turn PCB Assembly (MOFU/BOFU Focus)

Mid-to-late stage buyers often have specific questions about whether quick turn assembly can meet their unique needs. Below are answers to the most frequently asked长尾问句 (long-tail questions):

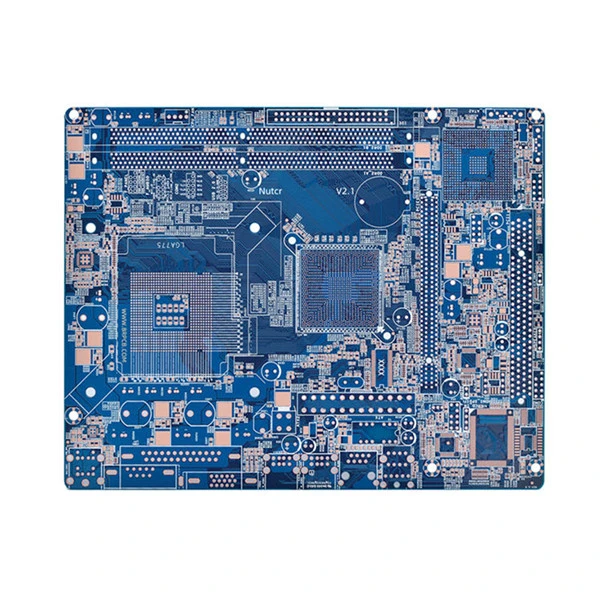

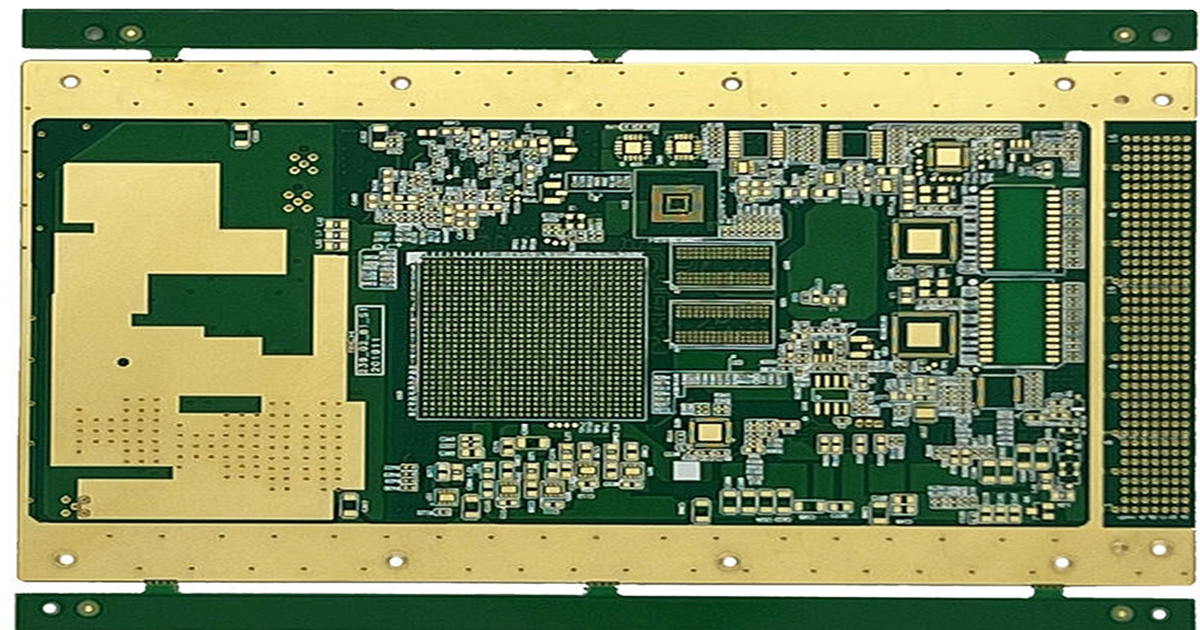

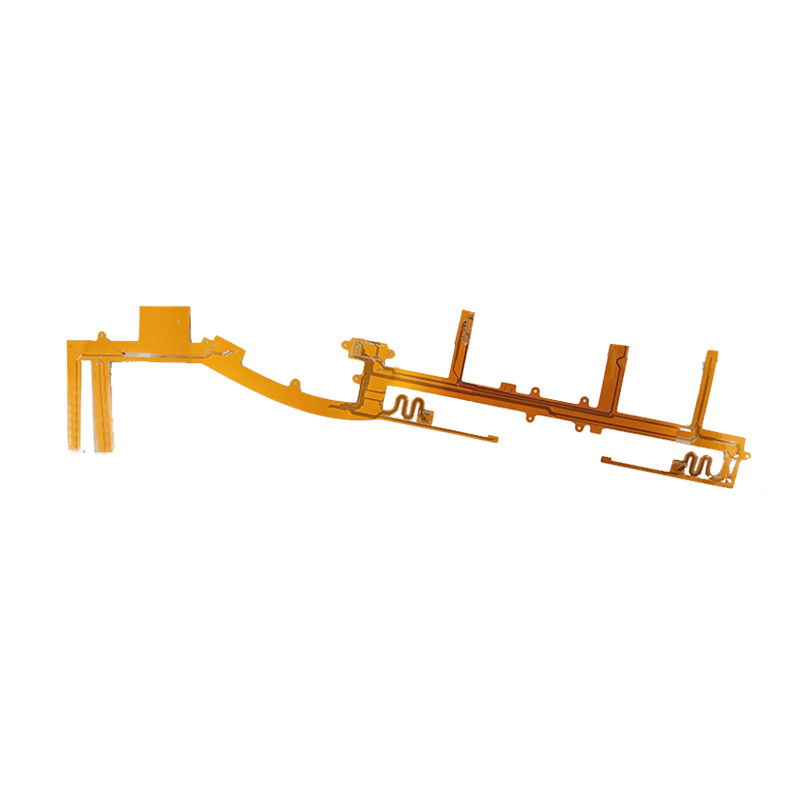

- Can quick turn PCB assembly handle complex multi-layer boards? Yes, reputable providers can assemble multi-layer boards (up to 40+ layers) with features like blind/buried vias, microvias, and controlled impedance—critical for high-frequency or high-density applications like aerospace and telecommunications equipment.

- Will quick turn assembly compromise the quality of my PCB? No, when working with a certified manufacturer, quick turn assembly maintains the same quality standards as traditional assembly. Top providers achieve first-pass yield rates of 95–98%, only slightly lower than traditional methods (98–99%), with a customer return rate of less than 1%.

- How do I choose the right quick turn PCB assembly manufacturer for my medical device project? Prioritize manufacturers with ISO 13485 certification (for medical devices), a proven track record in your industry, and transparent communication about lead times and quality controls. Look for case studies specific to medical devices to verify their expertise.

- What is the typical lead time for a 4-layer quick turn PCB assembly? For a standard 4-layer FR-4 board (100x100mm, 1.6mm thick), lead times range from 3–5 days. Simple 2-layer boards can be delivered in 24–48 hours, while complex boards with custom materials may take up to 7 days.

- Quick Turn PCB Assembly Fabrication: Process and Key Steps

The fabrication and assembly process for quick turn PCBs is streamlined but not rushed—each step is optimized for speed while maintaining quality. Below is a detailed breakdown of the process, designed as an independent answer unit for buyers researching how quick turn services work.

2.1 Pre-Assembly Preparation (Critical for Speed)

The pre-assembly stage sets the foundation for quick turnaround, as delays here can extend lead times significantly. Reputable manufacturers use the following optimized steps:

- Design Submission and DFM Review: Customers submit Gerber files, BOM (Bill of Materials), and assembly drawings via an online portal. The manufacturer conducts a rapid DFM review (usually within 2–4 hours) to identify design flaws that could slow production, such as incorrect trace spacing or unavailable components.

- Component Sourcing: Quick turn manufacturers leverage just-in-time (JIT) inventory systems and AI-driven component sourcing to avoid delays. Top providers maintain partnerships with global component suppliers, ensuring access to hard-to-find parts in hours rather than days.

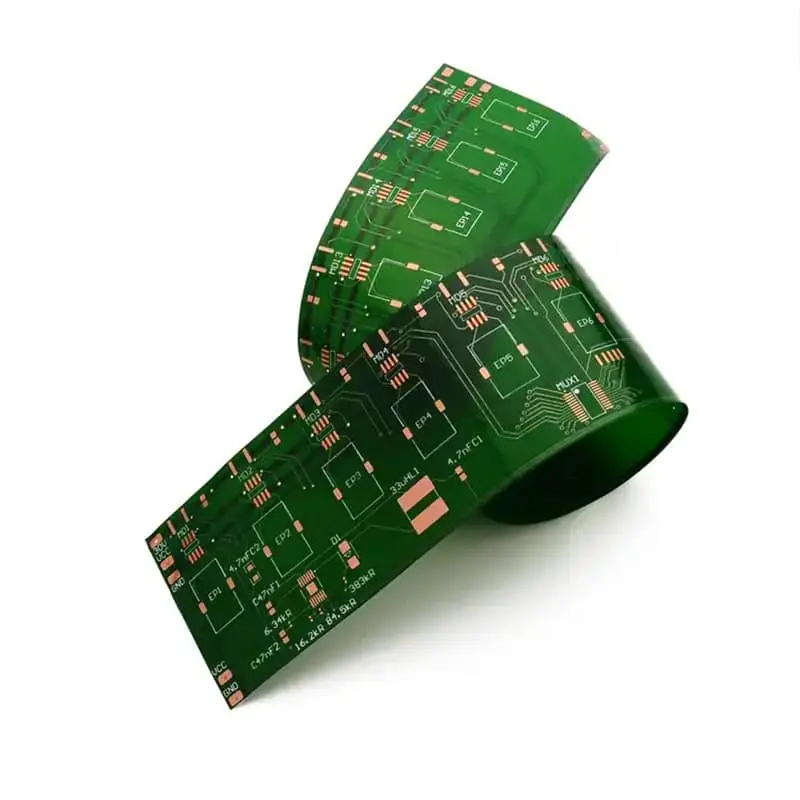

- Material Preparation: Standard materials (like FR-4) are kept in stock, while custom materials (like polyimide for high-temperature applications) are sourced quickly. This eliminates wait times for material delivery, a common bottleneck in traditional assembly.

2.2 Core Fabrication and Assembly Steps

Once pre-assembly is complete, the fabrication and assembly process proceeds with automated tools to maximize speed and precision. Key steps include:

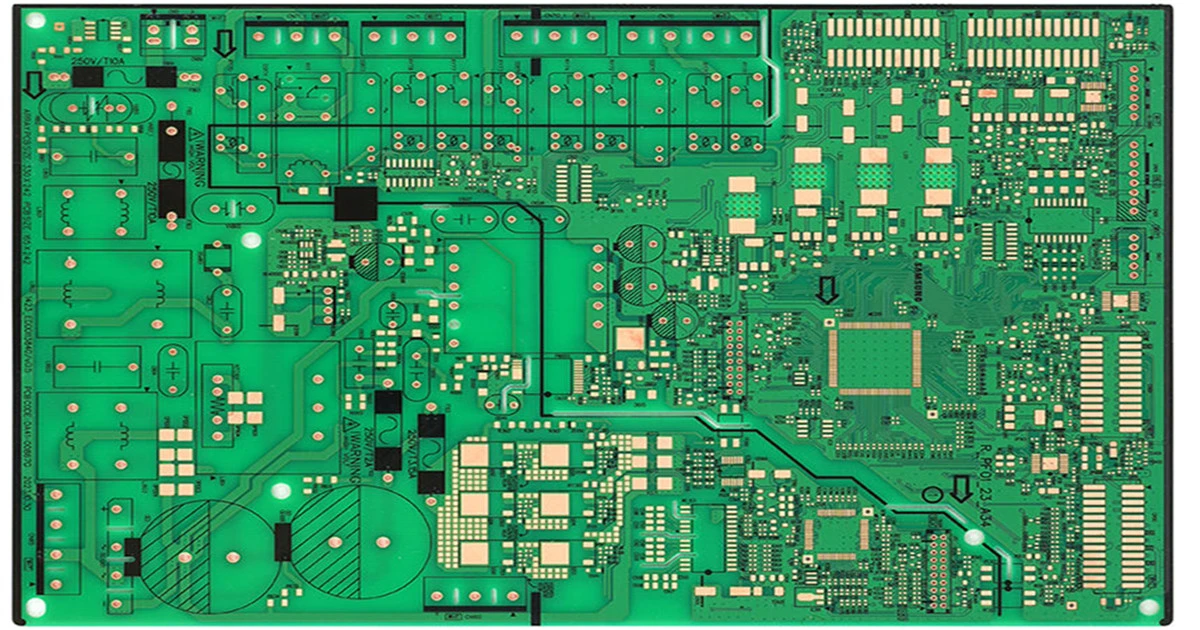

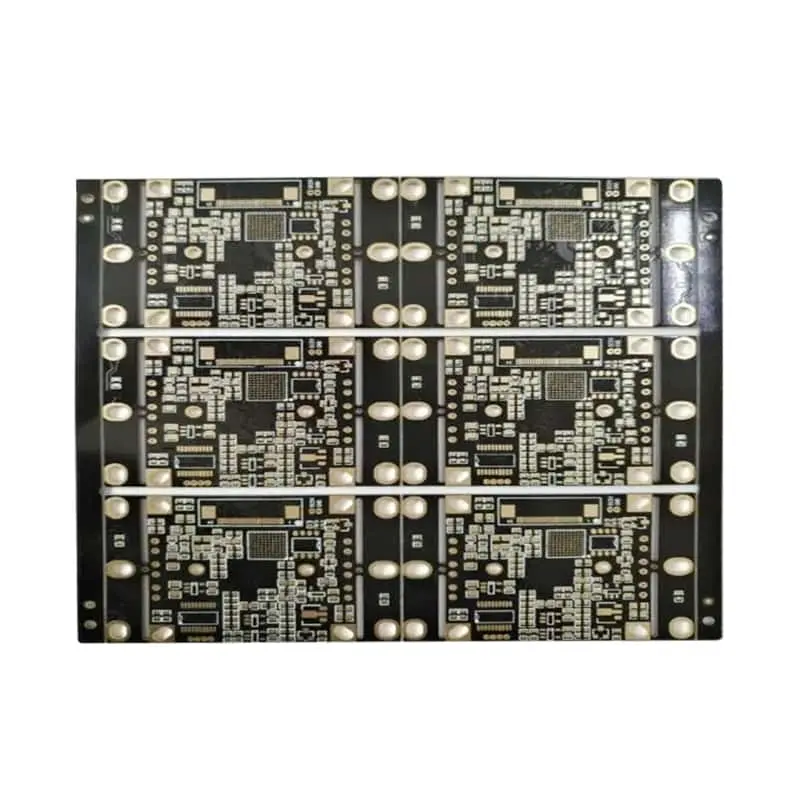

- PCB Fabrication: This involves drilling, etching, plating, solder masking, and silkscreening. Automated drilling machines and chemical etching processes reduce processing time, with most 2–4 layer boards fabricated in 12–24 hours.

- Solder Paste Printing: Automated printers apply solder paste to the PCB pads with high precision, ensuring strong component connections. This step is critical for reducing defects in quick turn assembly.

- Pick-and-Place Assembly: Robotic pick-and-place machines place surface-mount components (SMDs) on the PCB in minutes, even for complex layouts. Through-hole components are added manually or with automated insertion tools for larger parts.

- Reflow Soldering: The PCB is heated in a reflow oven to melt the solder paste, bonding components to the board. Quick turn manufacturers use optimized reflow profiles to reduce processing time without compromising solder quality.

- Inspection and Testing: Automated Optical Inspection (AOI) and X-ray testing (for hidden components) are used to detect defects quickly. Functional testing ensures the PCB performs as intended, with results delivered to the customer within hours of completion.

2.3 Key Technologies Enabling Quick Turn PCB Assembly

Quick turn assembly is only possible with advanced technologies that streamline processes and reduce human error. Below are the most critical technologies, relevant for BOFU buyers evaluating manufacturer capabilities:

- Automated Pick-and-Place Machines: High-speed machines that can place up to 100,000 components per hour, reducing assembly time by 50% compared to manual methods.

- AOI and X-Ray Inspection: These tools detect defects (like missing components or cold solder joints) in seconds, eliminating the need for time-consuming manual inspection.

- Cloud-Based Project Management: Allows customers to track order progress in real time, communicate with the manufacturer, and approve design changes quickly—critical for maintaining tight lead times.

- Modular Assembly Lines: Lines that can be reconfigured quickly for different PCB designs, reducing setup time between orders and enabling parallel processing of multiple projects.

- Quick Turn PCB Assembly Manufacturers: How to Choose the Right One (BOFU Focus)

For late-stage buyers ready to select a manufacturer, choosing the right partner is critical to ensuring speed, quality, and cost-effectiveness. This section provides actionable guidance, real case studies, and data to help make an informed decision.

3.1 Key Criteria for Selecting a Quick Turn PCB Assembly Manufacturer

When evaluating manufacturers, prioritize these criteria to avoid delays, quality issues, and unexpected costs—all critical for BOFU buyers:

- Certifications: Look for ISO 9001 (quality management), ISO 13485 (medical devices), TS 16949 (automotive), and UL certifications. These ensure compliance with industry standards and reduce the risk of non-compliant products.

- Lead Time Reliability: Choose a manufacturer with a 95–98% on-time delivery rate for quick turn orders. Avoid providers that overpromise (e.g., 24-hour delivery for complex boards) without a proven track record.

- Component Sourcing Capabilities: Verify that the manufacturer has partnerships with global component suppliers and can source hard-to-find parts quickly. This is critical for avoiding delays in emergency orders.

- Quality Control Processes: Ask about first-pass yield rates (target: 95%+), inspection methods (AOI, X-ray), and defect rates (target: 500–1000 defects per million units). Reputable manufacturers will share these metrics openly.

- Customer Support: Ensure the manufacturer offers 24/7 customer support for urgent orders and provides real-time order tracking. Late-stage buyers need transparency and quick communication if issues arise.

3.2 Real Case Study: How Quick Turn PCB Assembly Transformed a Medical Device Startup

To illustrate the impact of choosing the right quick turn manufacturer, here is a real case study with data support—critical for BOFU buyers seeking proof of value:

Company: A US-based medical device startup developing a portable glucose monitor.

Challenge: The startup needed to prototype a 6-layer PCB with custom components (polyimide material for biocompatibility) and deliver 50 functional units within 5 days for pre-clinical testing. Traditional manufacturers quoted 3–4 weeks, which would have delayed their FDA submission timeline by a month.

Solution: The startup partnered with a certified quick turn PCB assembly manufacturer (ISO 13485 certified) with expertise in medical devices. The manufacturer conducted a DFM review within 2 hours, sourced the custom polyimide material from a partner supplier, and used automated assembly and testing tools to meet the 5-day lead time.

Results:

- Delivered 50 functional PCBs in 4.5 days (ahead of schedule), with a first-pass yield rate of 96%.

- Identified 2 design flaws during DFM review, saving the startup $15,000 in rework costs and 2 weeks of delays.

- Enabled the startup to complete pre-clinical testing on time, submitting their FDA application 3 weeks earlier than planned.

- The startup continued to partner with the manufacturer for low-volume production, achieving a 98% on-time delivery rate over 12 months.

This case study demonstrates how the right quick turn manufacturer can solve time-critical challenges while maintaining quality—key for BOFU buyers in industries like medical devices.

3.3 Top Quick Turn PCB Assembly Manufacturers (2026 Data)

Below is a comparison of leading global manufacturers, focusing on metrics relevant to BOFU buyers (lead time, certifications, key capabilities). This table serves as an independent reference tool for evaluating options:

| Manufacturer</ | Minimum Lead Time</ | Certifications</ | Key Capabilities</ | On-Time Delivery Rate</ | Target Industries</ |

|---|---|---|---|---|---|

| China PCBA | 24 hours | ISO 9001, ISO 13485, TS 16949, UL | Multi-layer boards (up to 30 layers), SMT/THT mixed assembly, custom materials | 97% | Medical, industrial, telecommunications |

| Andwin Circuits | 48 hours | ISO 9001, IPC-A-610 | High-frequency boards, rigid-flex PCBs, AI-driven inspection | 96% | Aerospace, consumer electronics |

| LT PCBA | 72 hours | ISO 9001, ISO 13485 | Low-volume production (1–500 units), prototyping, functional testing | 98% | Medical, startups, research |

| Rigao Electronics | 48 hours | ISO 9001, UL | Complex multi-layer boards, emergency support, DFM optimization | 95% | Industrial, automotive, consumer electronics |

Note: Data is based on 2026 manufacturer reports and customer feedback. Lead times may vary based on board complexity and order volume.

- Gold Segment: Quick Turn vs. Traditional PCB Assembly (Independent Reference)

This gold segment provides a side-by-side comparison of quick turn and traditional PCB assembly, helping mid-to-late stage buyers determine which service best fits their needs. It is designed as an independent, easily referenceable tool for decision-making:

| Metric</ | Quick Turn PCB Assembly</ | Traditional PCB Assembly</ |

|---|---|---|

| Average Lead Time | 24 hours – 7 days | 2 – 6 weeks |

| First-Pass Yield Rate | 95 – 98% | 98 – 99% |

| Defects Per Million (DPMO) | 500 – 1000 | 50 – 500 |

| On-Time Delivery Rate | 95 – 98% | 85 – 95% |

| Ideal Order Volume | 1 – 1,000 units (low-volume, prototyping) | 1,000+ units (high-volume, mass production) |

| Cost Per Unit | Higher (due to expedited processes and low volume) | Lower (economies of scale for high volume) |

| Best For | Prototyping, emergency orders, low-volume production, time-sensitive launches | Mass production, long-term orders, cost-sensitive projects |

5、Conclusion: Is Quick Turn PCB Assembly Right for You?

Quick turn PCB assembly is a game-changing solution for businesses facing time-critical manufacturing challenges, from prototyping to emergency production. Its ability to deliver high-quality, functional PCBs in days rather than weeks accelerates time-to-market, reduces costs, and provides flexibility for low-volume orders—all key priorities for mid-to-late stage (MOFU/BOFU) buyers.

To determine if quick turn assembly is right for you, ask yourself: Do I need my PCBs in less than 2 weeks? Am I working on a low-volume order or prototype? Is time-to-market critical for my product’s success? If you answered “yes” to any of these, quick turn PCB assembly is likely the best choice.

When selecting a manufacturer, prioritize certifications, lead time reliability, quality control, and customer support. Use the case study and manufacturer comparison table in this article to evaluate options, and don’t hesitate to ask for references or sample work to verify their capabilities.

With the right quick turn PCB assembly partner, you can turn time-critical challenges into competitive advantages—launching products faster, reducing costs, and ensuring reliability in every order.

Authority Citation

According to the 2025 China Quick Turn PCB Market Research Report, the global quick turn PCB assembly market is growing at a CAGR of 15.8%, with China accounting for 40% of global market share. The report notes that “quick turn services are becoming increasingly critical for industries like medical devices and aerospace, where speed and precision are non-negotiable”. Additionally, IPC (Association Connecting Electronics Industries) states that quick turn assembly, when performed by certified manufacturers, meets the same quality standards as traditional assembly, making it a reliable choice for even the most demanding applications.